Technical data

E-1 laminated board formats

| FORMATS | ||

| STANDARD WIDTH (MM) | STANDARD LENGTH (MM) | GLOSS SCALE |

| 1850 | 900 / 1200 | 6-30o G (standard 20o G) |

| PRODUCT | APPLICATION | SEMI-FINISHED PRODUCTS | SURFACE FINISH | CONFECTION | PRODUCT PARAMETERS |

| Finish Foil | Veneering surfaces on tactile or roller presses | Chipboard, MDF, HDF and other wood-based semi-products |

1.The surface is finished with a final varnish (finish). Standard gloss 20G (at an angle of 600) Glosses available on request: 6-30G 2.Finish with a special primer that allows for further varnishing (additional varnish coating) 3.Foil without varnish (to be varnished after gluing to the board) |

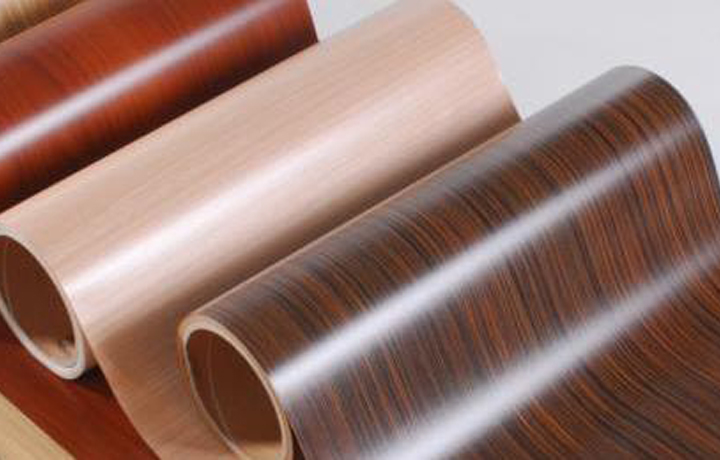

Packing in rolls with a width of 110 cm to 220 cm, depending on the decorative paper (standard 185 cm). It is possible to cut the roll into smaller widths. Roll length from 900 m to 1,300 m (max. roll diameter 500 mm). Inner diameter of the core 152mm, thickness of the core 5.5mm |

Base paper weight for various decors from 50 to 110 g/m2. Hygiene class: E-1 Surface resistance to chemicals and water vapour in accordance with PN-D 97017 and DIN 68861, part 1B to 1D. Storage: in original packaging, in closed rooms with a relative air humidity not exceeding 85%, for up to 6 months |

| Folia 2D (SOFT) | Covering profiles such as strips, frames, etc. | ||||

| Standard finish foil R4 IKEA |

Covering wood-based panels on tactile or roller presses |

Wood-based boards cut to the size | Varnishing with the use of highly specialized technologies | resistance particularly to scratches (3N), water (16 hours), mineral oil (24 hours) – in accordance with the IKEA requirements for R4 class surfaces | |

| Balancing foil | Covering invisible surfaces to prevent warping of the board that is covered with finish foil on one side | Chipboard, MDF, HDF and other wood-based semi-products | Surface with or without a varnish | Parameters depend on the type of surface finish | |

| Stabilizing foil | The foil is intended for the „back” sides of the tops and window sills covered with HPL laminate | Lacquered surface, finish-type final processing | Rigid foil impregnated with melamine and acrylic resins with a high degree of condensation. The board surface covered with it demonstrates high resistance to water vapour and moisture |

Packing

Single bales are secured with polyethylene foil, corrugated paper and plastic caps at the ends of the coils. Orders over three rolls are packed on pallets, the rolls are secured with polystyrene, and all of this is fastened with three steel straps.